How Drone Data is Creating Interactive 3D Models for Smarter Asset Management in Belgium

- Anton De Vis

- May 8

- 7 min read

Managing vast physical assets – from complex industrial plants and sprawling construction sites to vital public infrastructure – is a significant challenge for Belgian industries. Ensuring operational efficiency, predictive maintenance, and lifecycle optimization requires accurate, timely, and actionable data. Enter the digital twin, a groundbreaking concept powered by cutting-edge drone technology, that is revolutionizing how businesses interact with and manage their physical world.

This post will explore the transformative potential of digital twins created from drone data, explaining the technology in an accessible way and highlighting how Hovvr's services can provide the essential foundation for this advanced approach to asset lifecycle management in Belgium.

Understanding Digital Twins: More Than Just a 3D Model

So, what exactly is a "digital twin," and how does it go beyond a standard 3D model?

In simple terms, a digital twin is a dynamic, virtual replica of a physical asset, process, or system.Think of it as a living, breathing digital counterpart that is continuously updated with data from its real-world twin. This "live" connection is what makes it interactive and incredibly powerful.

How do Digital Twins differ from traditional CAD or static 3D visualizations?

Static vs. Dynamic: Traditional CAD models are primarily design blueprints, often created before an asset exists and not always updated to reflect its current state. Static 3D visualizations are for presentation or a snapshot in time. A digital twin, however, evolves with the physical asset throughout its lifecycle.

Data Integration: Digital twins integrate real-time or near real-time data from various sources, including sensors, IoT devices, and, crucially, drone surveys. This data provides insights into performance, condition, and operational context.

Interactivity & Analysis: Users can interact with a digital twin to query information, run simulations ("what-if" scenarios), analyze performance, and predict future states without impacting the real-world asset.

Core components of a useful digital twin for industrial assets include:

Accurate Geometric Representation: A precise 3D model forming the visual and spatial backbone.

Linked Data: Connection to operational data, maintenance records, sensor readings, and other relevant information systems.

Ability to Simulate or Analyze: Tools to test hypotheses, optimize processes, or forecast outcomes (e.g., wear and tear, energy consumption).

Synchronization: Regular updates to ensure the digital twin accurately mirrors the physical asset.

The Power of Drone Data: Building the Foundation

Creating and maintaining an accurate, high-fidelity digital twin of existing structures, vast sites, or complex facilities relies heavily on rich data – and drones are uniquely positioned to deliver it.

How is drone data foundational?

Drones equipped with advanced sensors capture comprehensive data with remarkable speed and accuracy:

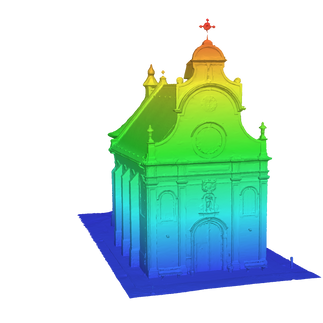

Photogrammetry: High-resolution cameras capture overlapping images, which are processed to create detailed 3D mesh models and orthomosaics, rich in visual detail.

LiDAR (Light Detection and Ranging): LiDAR sensors emit laser pulses to measure distances, generating dense and highly accurate 3D point clouds, even in complex environments or low-light conditions. This is ideal for capturing precise geometry.

Thermal Imaging: Thermal cameras detect temperature variations, invaluable for identifying heat loss, water ingress, electrical faults, or machinery overheating within assets.

The Process: From Drone Data to Digital Twin Foundation

Flight Planning & Data Capture: Drone flights are meticulously planned to ensure optimal coverage and data quality (e.g., image overlap, Ground Sample Distance - GSD).

Data Processing: Specialized software (e.g., photogrammetry engines like Pix4D or DJI Terra, or platforms like Bentley ContextCapture) processes the raw drone data – correcting for GPS inaccuracies (often enhanced with RTK/PPK technology), georeferencing images, and reconstructing the environment.

Model Generation: The output is a high-fidelity 3D model – typically a point cloud (in formats like LAS, LAZ, E57) or a textured mesh (OBJ, FBX) – that forms the precise geometric base of the digital twin.

Platform Integration: This model is then imported into a digital twin platform (e.g., Autodesk Construction Cloud, Bentley iTwin Platform, or solutions offered by SAS) where it's linked with other data sources.

Keeping Digital Twins Current:

Physical assets change. Construction sites progress, machinery wears down, and infrastructure degrades. Drones offer an efficient way to regularly resurvey assets, capturing these changes. This new data is fed back into the digital twin, ensuring it remains an up-to-date and reliable representation of its physical counterpart.

Unlocking Benefits for Asset Management in Belgium

For Belgian businesses, implementing digital twins for their assets offers a wealth of practical advantages:

Improved Maintenance:

Predictive Maintenance: By analyzing data trends within the digital twin (e.g., thermal anomalies from drone inspections), potential failures can be predicted, allowing for proactive maintenance scheduling, reducing downtime and costs.

Safer, Easier Remote Inspection: Drones can access hazardous or hard-to-reach areas, reducing risks for human inspectors. The resulting data allows for detailed remote visual and thermal inspections via the digital twin.

Better Planning of Repairs: Accurate 3D models help in precisely locating defects and planning repair logistics more effectively.

Enhanced Collaboration:

A digital twin serves as a centralized, single source of truth for diverse teams (engineering, operations, maintenance, external contractors). All stakeholders in Belgium can access and interact with the same consistent information, improving communication and decision-making.

Smarter Operations:

Simulation of Changes: Test the impact of layout modifications in a factory, new equipment installation, or altered operational workflows within the virtual environment before committing resources in the real world.

Optimizing Layouts & Processes: Analyze spatial data and operational metrics to identify bottlenecks and improve efficiency.

Training in Virtual Environments: Provide immersive training for staff on complex procedures or emergency responses using the digital twin.

Construction Progress & Quality:

Accurate As-Built vs. As-Designed Tracking: Regularly updated drone data allows for precise comparison of construction progress against BIM (Building Information Modeling) designs.

Clash Detection & Quality Control: Identify discrepancies or potential issues early, reducing rework and ensuring quality standards. The Port of Antwerp-Bruges, for instance, is leveraging digital twin technology and BIM for more efficient collaboration and project management.

Lifecycle Management & The "Golden Thread":

Gain a deeper understanding of an asset's condition and performance over its entire lifecycle. This supports better-informed decisions on refurbishment, retrofitting, or decommissioning.

Digital twins are crucial for creating a "golden thread" of information – a complete and accurate digital record of an asset's design, construction, and operational history. This concept, gaining traction globally, is highly relevant for fulfilling documentation requirements like the Belgian Post-Intervention File (PIF) for construction projects, ensuring safety and transparency.

Compliance and Reporting:

Digital twins can significantly simplify compliance with safety regulations by providing auditable records of inspections and asset conditions.

They can also support ESG (Environmental, Social, Governance) reporting by enabling better tracking of energy consumption, emissions (as highlighted by Agoria's studies on CO2 reduction potential in Belgian industry through digitalization), and resource management.

Implementation & Application in the Belgian Landscape

The adoption of digital twin technology is gaining momentum in Belgium. A 2023 PwC survey indicated that 10% of Maintenance & Asset Management departments in North-West Europe (including Belgium) have already implemented digital twins, with significant interest in further exploration.

Which industries and assets in Belgium stand to gain the most?

Construction & Real Estate Development: For progress monitoring, quality control, BIM integration, and creating digital records for property portfolios.

Manufacturing (Factories, Plants): For layout optimization, predictive maintenance of machinery, and process simulation.

Utilities (Energy, Water): For managing extensive networks (e.g., pipelines, grids, substations like those managed by Elia), remote inspections, and predictive maintenance. The Port of Antwerp-Bruges is a flagship example, developing a digital twin of its port area, incorporating drone data and 5G for smarter, safer operations.

Public Infrastructure Management: For bridges, roads, railways, and urban environments. The DUET project in Flanders, for example, uses digital twins for urban planning, simulating traffic and air quality.

Research and Innovation: Belgian research hubs like Imec are at the forefront, developing open-source frameworks and fostering collaborations (e.g., "City of Things" initiatives in Antwerp and Bruges) to advance digital twin capabilities.

Software and Platforms:

A range of software solutions are used to host, visualize, and interact with digital twins created from drone data. These include major platforms like Autodesk Construction Cloud and Bentley iTwin Platform, which offer robust capabilities for integrating 3D models with diverse datasets. Other notable platforms include those from SAS, Siemens, GE, and NVIDIA Omniverse. The data captured by drones (often in formats like .LAS, .LAZ, .E57 for point clouds, and .OBJ, .FBX for meshes, or integrated with .IFC for BIM) is compatible with these leading systems.

Navigating the Path to Digital Twins: Considerations

Embarking on a digital twin strategy requires careful planning. Key considerations include:

Initial Investment: Costs for data acquisition, software, integration, and skilled personnel.

Data Management & Integration: Handling large volumes of data from diverse sources and ensuring interoperability.

Skills Gap: The need for expertise in data science, 3D modeling, and digital twin platform management.

Cybersecurity: Protecting sensitive asset data within the digital twin environment.

Scalability: Ensuring the solution can grow with your needs and increasing data loads.

Building a Business Case: Clearly defining the objectives and quantifying the potential ROI, a challenge noted by some Belgian firms.

Despite these challenges, a phased approach, focusing on specific high-impact use cases, can demonstrate value quickly and build momentum for wider adoption. The long-term benefits in efficiency, cost savings, risk reduction, and improved decision-making often far outweigh the initial hurdles.

How Hovvr Empowers Your Digital Twin Strategy

At Hovvr, we understand that the foundation of any powerful digital twin is accurate, reliable, and comprehensive data. Our advanced drone surveying, mapping, and inspection services provide precisely that:

High-Quality Data Acquisition: We leverage state-of-the-art drone technology equipped with high-resolution cameras, LiDAR, and thermal sensors to capture the detailed geometric and conditional data essential for creating robust digital twins.

Precision and Accuracy: Our expertise in flight planning and data processing ensures the delivery of georeferenced, survey-grade 3D point clouds, textured meshes, and orthomosaics tailored to your specific project requirements.

Data Ready for Integration: We provide data outputs in industry-standard formats, ready to be seamlessly integrated into leading digital twin platforms and BIM workflows.

Whether you are looking to create a digital twin for a complex industrial facility, a new construction project, or an extensive infrastructure network, Hovvr provides the critical data foundation to bring your physical assets into the digital age.

The Future is Digital, The Future is Now

Digital twins, fueled by rich drone data, are no longer a futuristic concept but a practical and increasingly accessible solution for smarter asset management in Belgium. They offer an unprecedented ability to understand, manage, and optimize physical assets throughout their lifecycle. By embracing this technology, Belgian industries can unlock new levels of efficiency, enhance collaboration, improve safety, and gain a significant competitive advantage.